Movement of air pollutants through the Mg-Si Furnace

MG-Si Simulations

Our dedication to environmental protection is ingrained in every stage of our operations. Specifically, during the smelting process of Metallurgical Grade Silicon (MG-Si), we prioritize minimizing carbon, SOx and NOx emissions. Such considerations begin right from the early engineering stages of our production processes.

Simulated Conditions inside the Poly-Si Reactor

Poly-Si CFD Simulations

To ensure the highest levels of excellence, especially in terms of chemical mixability, we harness the power of Computational Fluid Dynamics (CFD) simulations. This approach allows us to modify design and operational parameters in line with production requirements.

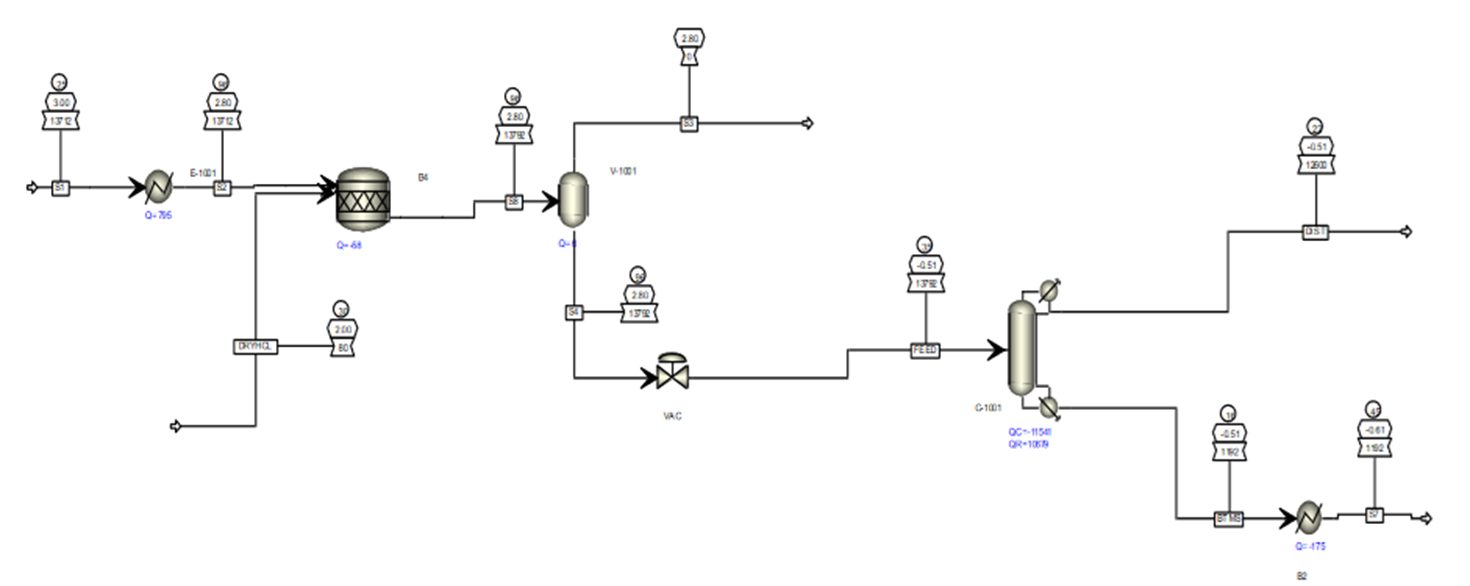

Simulation of slurry recovery process

Poly-Si Plantwide Simulations

We harness the power of Plantwide Models to gain a comprehensive understanding of material flows within our facilities. These models serve as invaluable tools that enable us to analyze, optimize, and design our plants with a focus on achieving optimal results in purity, yield, and energy consumption.

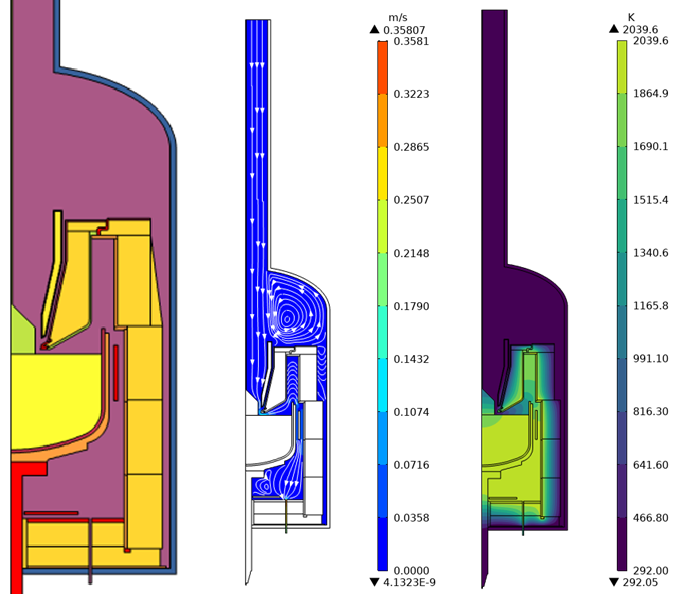

Cross section of Ingot puller, Velocity streamlines, and temperature

Ingot Simulations

We constantly strive to deliver exceptional silicon ingot production solutions through continuous research and development. To ensure the highest quality and efficiency in our Ingot manufacturing process, we have a dedicated Cz-Puller, that is aligned to check and evaluate design modifications.

Concentration of reactant chemicals inside the furnace

Cell Simulations

In the production of PERC and TOPCon cells, we employ a meticulous approach that involves simulating our equipment to minimize non-uniformity across various layers. This simulation process is instrumental in crafting cells that deliver maximum efficiency, also ensuring minimal variation in their performance.

Structural bending of Module under wind load

Module Simulations

Our structural simulations (FEA) predict the performance of load-carrying structures, allowing us to optimize the weight-strength ratio. Virtual MLT testing of module frames accelerates product development, reducing the need for extensive physical testing.